Supply chain optimization focuses on improving a supply chain’s performance by streamlining its processes. This involves reducing costs, improving responsiveness, and ensuring that products and services meet customer expectations.

Businesses today face challenges like fluctuating demands, supply chain disruptions, and global competition, making optimization a critical aspect of operations. Through the use of supply chain optimization techniques, businesses can ensure smooth operations, mitigate risks, and gain a competitive edge.

Integrating SaaS (Software as a Service) platforms in supply chain management has taken this optimization to new heights, offering real-time insights and seamless scalability.

What is Supply Chain Optimization?

Supply chain optimization focuses on aligning supply chain activities to achieve cost efficiency, improve delivery times, and maximize profits. The process addresses key areas such as inventory management, supplier performance, and logistics efficiency.

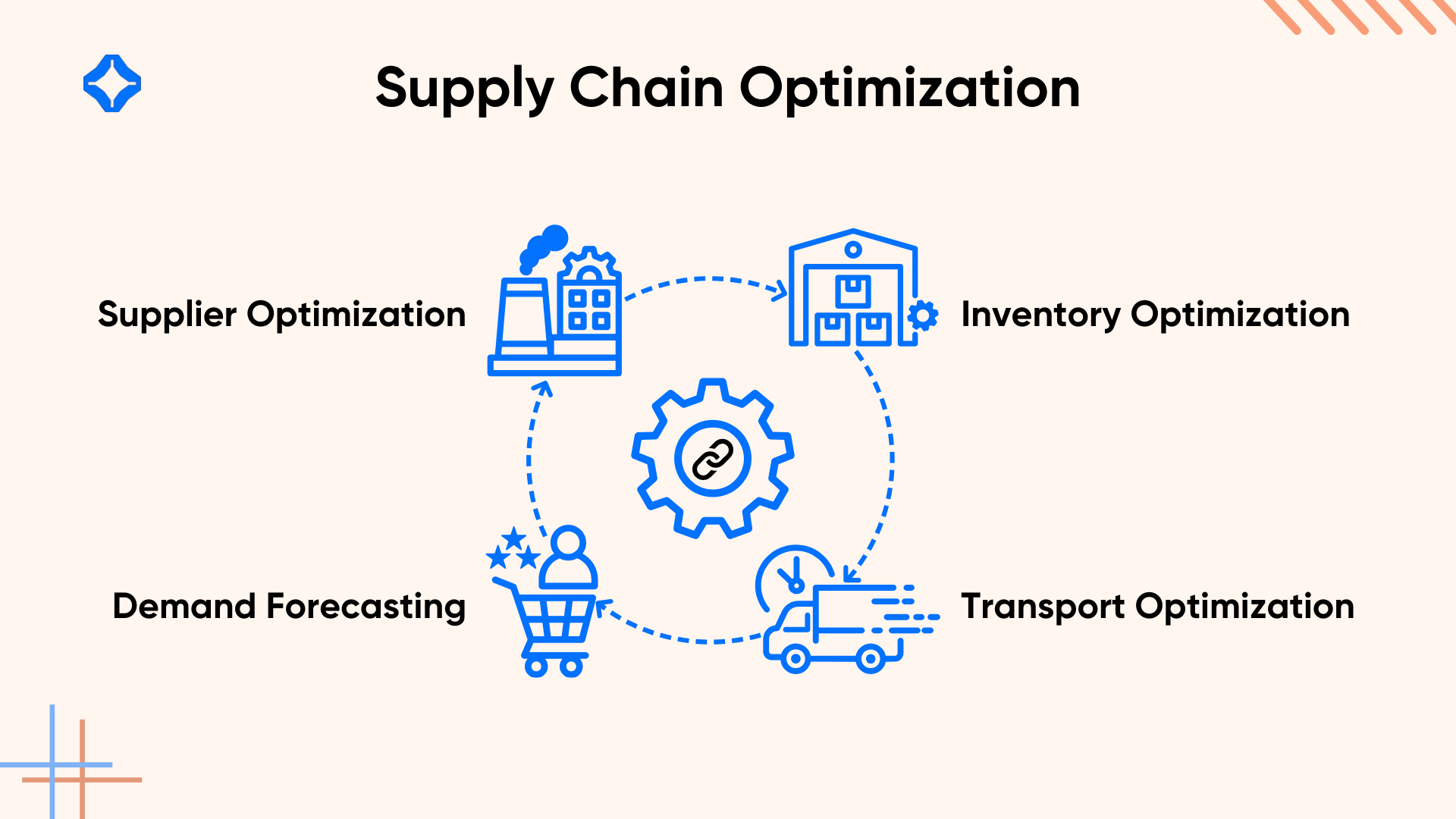

Key components of supply chain network optimization include:

- Inventory Optimization: Balancing supply and demand to minimize costs and avoid shortages.

- Transportation Optimization: Streamlining delivery routes and reducing fuel costs.

- Supplier Optimization: Evaluating suppliers to ensure cost-effective procurement.

- Demand Forecasting: Using predictive analytics to anticipate market trends.

These combined efforts optimize supply chain management, allowing businesses to adapt to market changes effectively.

The Role of SaaS in Supply Chain Optimization

SaaS platforms play a transformative role in modern supply chain optimization by introducing agility, scalability, and efficiency to business processes. These tools are suitable for the dynamic needs of supply chain planning and optimization by enabling seamless collaboration, automating complex workflows, and ensuring cost efficiency.

How SaaS Optimize Supply Chain Management

SaaS platforms offer businesses the ability to adapt to challenges and scale operations without investing heavily in traditional infrastructure. Below are the key ways SaaS tools optimize supply chain processes

1. Real-Time Data Integration

SaaS solutions provide a complete overview of the entire supply chain network. They ensure real-time updates on critical operations such as inventory levels, orders, and shipment statuses. This level of transparency helps businesses anticipate potential disruptions, enabling preventive adjustments to supply chain strategies.

For example, with SaaS-based supply chain optimization models, businesses can track warehouse inventories in real-time and align them with transportation schedules to avoid delays and overstocking.

2. Scalability for Growing Needs

SaaS platforms are designed to scale alongside business growth, making them ideal for supply chain network optimization. Whether a company is expanding its operations globally or introducing new distribution centers, SaaS tools seamlessly accommodate increased complexity.

For example, businesses experiencing seasonal demand spikes can use scalable SaaS solutions to adjust supply chain resources without overcommitting to long-term infrastructure investments.

3. Automation of Workflows

Automated tools within SaaS platforms significantly reduce manual efforts in supply chain management optimization. Streamlining tasks such as order processing, demand forecasting, and inventory tracking allows teams to concentrate on strategic decision-making.

These automation capabilities also support supply chain adjustment during unexpected events, ensuring smooth operations despite market fluctuations or logistical challenges.

4. Cost Reduction through Cloud-Based Infrastructure

One of the unique advantages of SaaS platforms is their ability to lower operational costs. Businesses save significantly on IT expenses by eliminating the need for on-premises servers and maintenance.

SaaS tools offer cost-effective solutions for supply chain optimization techniques, such as transportation planning and logistics management. Businesses can also leverage SaaS tools to implement supply chain adjustment strategies that minimize waste, reduce energy consumption, and optimize delivery routes, further cutting expenses.

Benefits of SaaS in Supply Chain Optimization

The adoption of SaaS platforms in supply chain network optimization introduces game-changing advantages, empowering businesses to manage their operations with greater efficiency, flexibility, and precision.

1. Improved Decision-Making

With SaaS solutions, businesses gain access to real-time data and advanced analytics, enabling smarter, faster decisions. By utilizing supply chain optimization techniques, these platforms analyze trends, forecast demand, and identify potential issues before they escalate into major problems.

For example, predictive analytics within SaaS platforms can monitor inventory levels, production schedules, and transportation delays, allowing companies to proactively adjust their supply chain strategies.

Key advantages include:

- Minimizing downtime during supply chain disruptions.

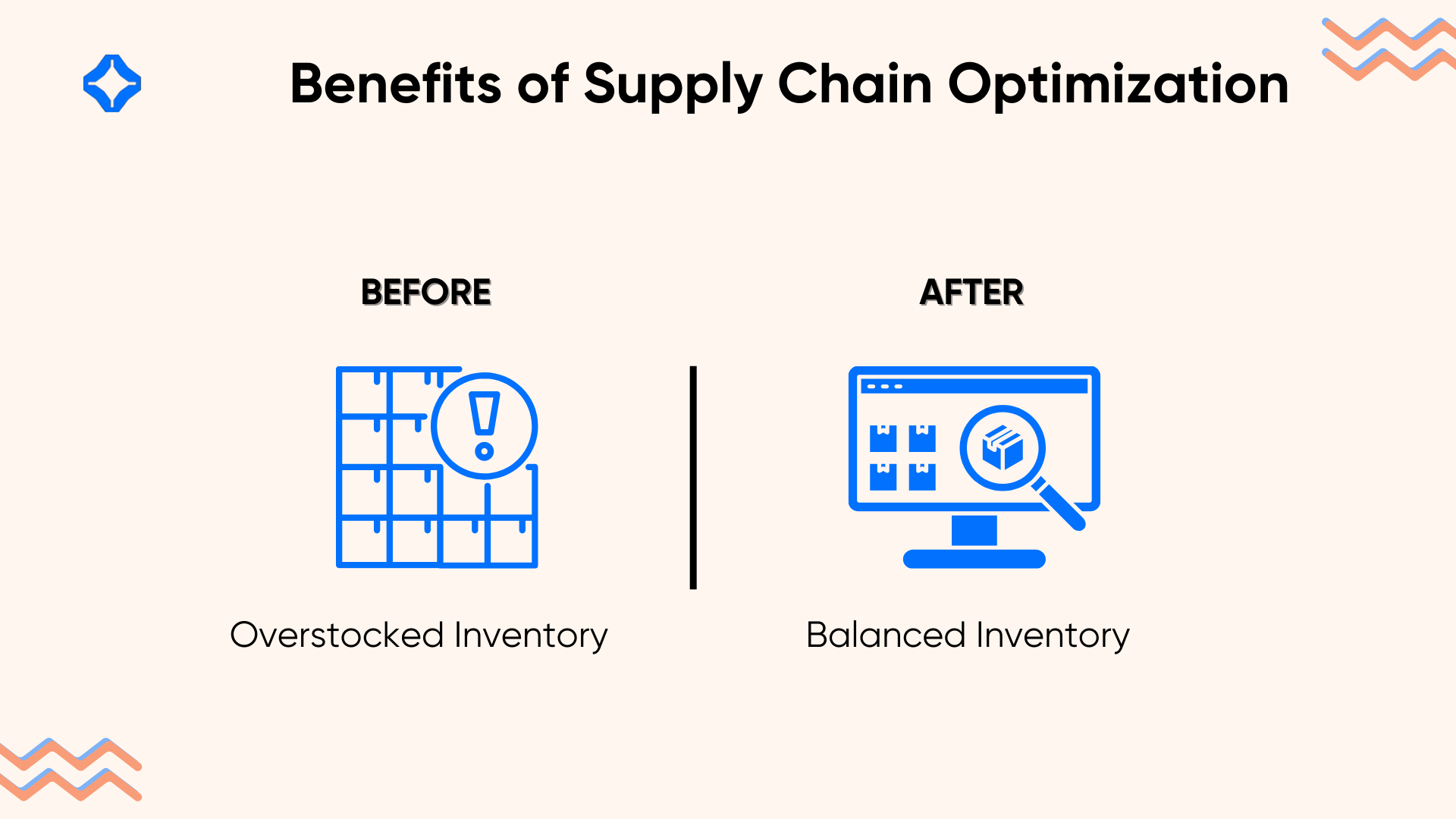

- Balancing inventory to prevent overstocking or shortages.

- Optimizing resource allocation for maximum efficiency.

2. Enhanced Collaboration

Collaboration is crucial in supply chain management optimization, and SaaS tools make it seamless by offering centralized dashboards and shared analytics. These platforms allow all stakeholders, including suppliers, manufacturers, and logistics providers, to work in harmony by accessing the same data in real-time.

For example, a supplier can use SaaS-powered supply chain planning & optimization tools to align production schedules with downstream demand, ensuring timely deliveries.

Collaboration benefits include:

- Real-time visibility into order statuses and inventory levels.

- Faster resolution of bottlenecks and logistical challenges.

- Improved trust and communication between partners.

3. Global Reach and Scalability

Modern supply chain optimization models often involve operations in different countries. SaaS platforms ensure consistent performance across diverse regions, supporting business expansion globally.

By employing remote project management principles helps international teams coordinate tasks seamlessly across different time zones.

For example, a business using SaaS for supply chain adjustment can quickly adapt to changes in trade policies, tariffs, or market demand across different countries, ensuring uninterrupted operations.

Key benefits include:

- Scaling operations during seasonal demand surges.

- Streamlining cross-border logistics for cost-effective shipping.

- Adapting to regional compliance and regulations.

Challenges in Supply Chain Optimization

While supply chain planning optimization offers numerous advantages, businesses often face significant challenges in ensuring smooth operations. Overcoming these obstacles requires a combination of robust supply chain optimization solutions, advanced technologies, and strategic planning.

1. Data Silos

Fragmented systems within the supply chain create disconnected data sources, leading to inefficiencies and poor decision-making. This lack of integration prevents stakeholders from accessing a unified view of the supply chain network.

For example, if inventory data from warehouses isn’t synchronized with demand forecasts, it can lead to overstocking or shortages. SaaS platforms address this issue by centralizing data ensuring seamless communication across departments and partners.

Key impacts of data silos include:

- Delayed decision-making due to incomplete or outdated information.

- Increased operational costs from redundant processes.

- Reduced responsiveness in responding to market changes.

Solutions:

Deploy SaaS-based supply chain optimization models to integrate data from procurement, manufacturing, logistics, and sales, enabling a cohesive approach to supply chain network optimization.

2. Unpredictable Disruptions

Due to their global reach, supply chains face heightened risks from unexpected disruptions such as natural disasters, geopolitical conflicts, pandemics, and economic fluctuations. These events can lead to delays, increased costs, and strained supplier relationships, affecting optimization in supply chain management.

For example:

- A hurricane affecting transportation routes can delay deliveries.

- Trade policy changes can disrupt sourcing from international suppliers.

Challenges include:

- Adapting quickly to changing circumstances.

- Managing fluctuating demand and supply during crises.

- Mitigating risks associated with supplier dependency.

Solutions:

Businesses can implement powerful supply chain adjustment strategies, including:

- Real-time monitoring through SaaS platforms with predictive analytics.

- Diversifying suppliers to mitigate supply chain risk from single sources.

- Developing contingency plans for critical supply chain activities.

3. Cost Management

A key challenge in supply chain management optimization is finding the right balance between cost efficiency and high service standards. Without proper strategies, businesses risk cutting corners that compromise customer satisfaction or operational efficiency.

Key cost-related challenges:

- Rising transportation and fuel costs.

- High expenses related to warehousing and inventory management.

- Balancing labor costs while maintaining production timelines.

Solutions:

Businesses can leverage supply chain optimization techniques such as:

- Using financial automation tools can streamline budgeting, invoicing, and cost tracking throughout the supply chain.

- Using advanced supply chain optimization tools to identify cost-saving opportunities.

- Delivery route optimization to reduce fuel costs and improve delivery speed.

Key Techniques for Supply Chain Optimization

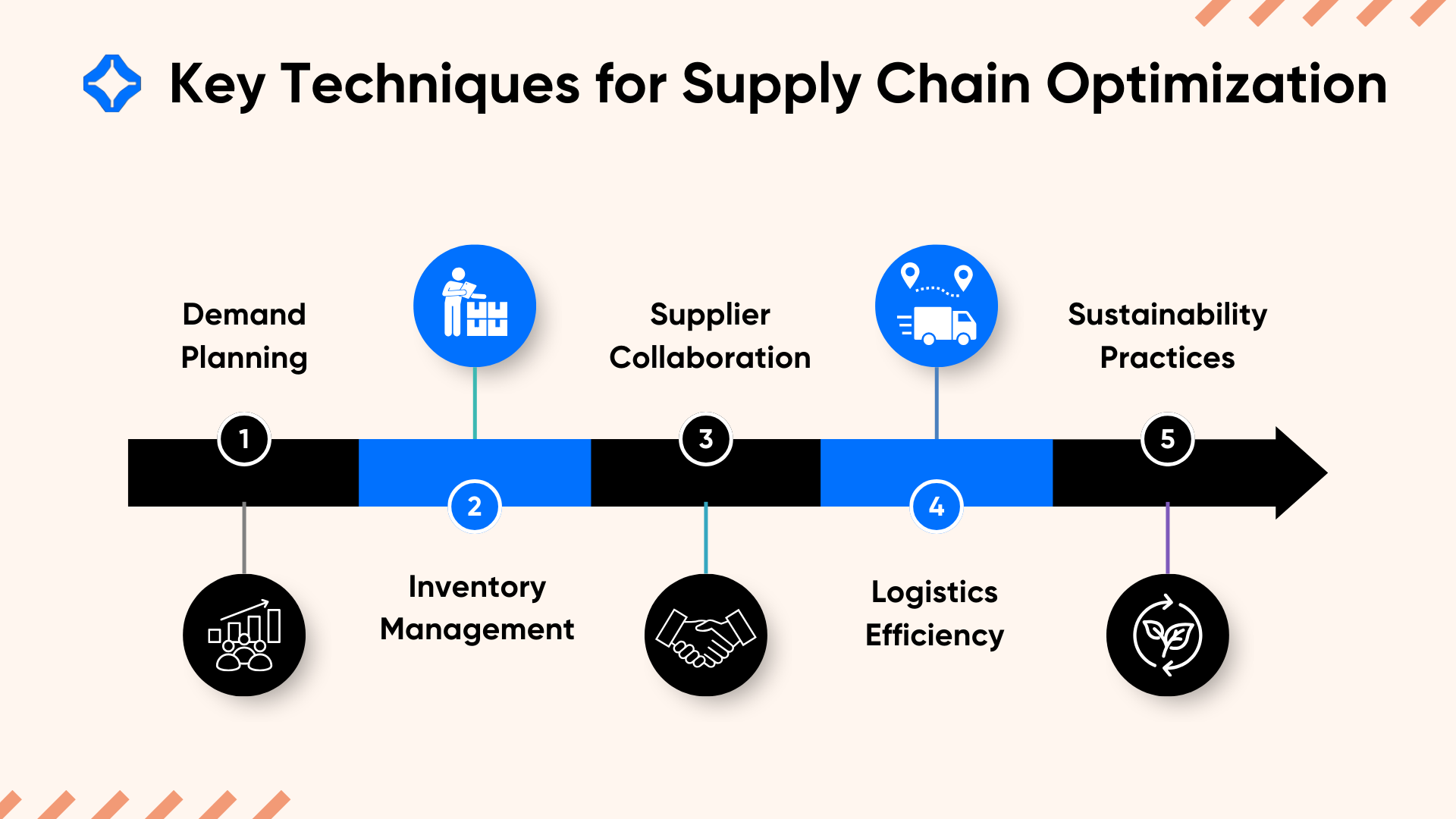

To achieve peak efficiency in supply chain network optimization, businesses must adopt innovative techniques that address various aspects of supply chain operations.

1. Demand Planning

Accurately forecasting customer demand is critical for minimizing waste and ensuring smooth operations. SaaS-based predictive analytics plays a pivotal role by analyzing historical sales data, market trends, and external factors to anticipate demand fluctuations.

Example:

- A business may use demand forecasting to adjust production levels ahead of seasonal sales peaks, ensuring products are available when needed.

2. Inventory Management

Effective inventory management is important for successful supply chain planning and optimization. Advanced tools like AI-driven systems monitor stock levels, predict restocking needs, and minimize waste.

Key Features:

- Real-time inventory tracking across multiple locations.

- Alerts for low stock or excess inventory.

3. Supplier Collaboration

Building strong relationships with suppliers is paramount for achieving a seamless and resilient supply chain. Transparent communication and performance evaluations ensure that suppliers meet quality, cost, and delivery expectations.

Techniques:

- Shared dashboards for real-time updates on orders and shipments.

- Conducting periodic performance reviews to identify areas for development and growth.

4. Logistics Efficiency

Transportation and logistics are often the most challenging aspects of supply chain management. Optimizing these processes ensures timely and cost-effective delivery of goods.

Strategies:

- Utilizing real-time tracking tools to monitor shipments and anticipate delays.

- Utilizing route optimization software to find the fastest and most fuel-efficient delivery paths.

5. Sustainability Practices

Incorporating eco-friendly practices into the supply chain is no longer optional but necessary in today’s business landscape. The goal of sustainability practices in supply chain management is to reduce environmental impact while optimizing operational performance.

Examples:

- Using eco-friendly materials in packaging and production.

- Optimizing delivery routes to lower fuel consumption and carbon emissions.

By implementing these supply chain optimization techniques, businesses can create a resilient, efficient, and customer-focused supply chain that adapts to market dynamics and supports long-term success.

Examples of Supply Chain Optimization

- Retail Industry: Retailers use supply chain optimization techniques to maintain inventory accuracy and improve customer satisfaction.

- Healthcare Sector: Hospitals utilize supply chain network optimization to guarantee the timely delivery of essential medical supplies.

- E-Commerce: Online platforms rely on ecommerce automation and supply chain optimization to manage high order volumes efficiently.

Conclusion

In today’s business landscape, supply chain optimization has become a critical factor for success. Integrating SaaS-based solutions into supply chain network optimization offers unmatched efficiency, real-time visibility, and seamless operations.

Advanced technologies like AI, IoT, and blockchain are transforming supply chain planning & optimization, paving the way for more resilient, sustainable, and profitable outcomes. By adopting these tools, companies can ensure their supply chain management optimization meets global demands while driving growth and efficiency.

FAQs: Supply Chain Optimization and SaaS

Supply chain optimization involves refining processes like inventory management, transportation, and supplier collaboration to achieve maximum efficiency and cost savings.

SaaS platforms provide real-time data, scalability, and automation, enabling businesses to adapt quickly and optimize supply chain performance.

Key advantages include reduced costs, improved delivery times, improved supplier performance, and better customer satisfaction.

Techniques include demand forecasting, inventory optimization, supplier performance evaluation, and logistics automation.

Optimizing the supply chain helps businesses remain competitive, reduce risks, and respond effectively to market changes.